BIKAR Metals companies

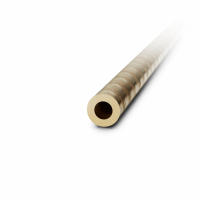

Very good cold forming and good hot forming., Copper-nickel alloys are among the most corrosion-resistant copper materials, Resistant to moisture, non-oxidising acids, alkalis and salt solutions, organic acids and dry gases such as oxygen, chlorine, hydrogen chloride, hydrogen fluoride, sulphur dioxide and carbon dioxide.

Very good cold forming and good hot forming., Copper-nickel alloys are among the most corrosion-resistant copper materials, Resistant to moisture, non-oxidising acids, alkalis and salt solutions, organic acids and dry gases such as oxygen, chlorine, hydrogen chloride, hydrogen fluoride, sulphur dioxide and carbon dioxide.

good resistance to seawater, various agents and industrial atmosphere, very good tarnish resistance

good resistance to seawater, various agents and industrial atmosphere, very good tarnish resistance

good resistance to seawater, various agents and industrial atmosphere, very good tarnish resistance

good resistance to seawater, various agents and industrial atmosphere, very good tarnish resistance

very good cold forming, good hot forming, good resistance in natural atmosphere (also sea air) and industrial atmosphere, practically insensitive to stress corrosion cracking

Very good weldability, Very good corrosion resistance to normal atmosphere, Very high electrical and thermal conductivity, Very good anodizing properties, also decorative, Very good formability

Very good welding properties, Very good corrosion resistance to a normal atmosphere , Very high electrical conductivity as well as thermal conductivity Very good anodising properties, also decorative, Very good malleability