CW352H

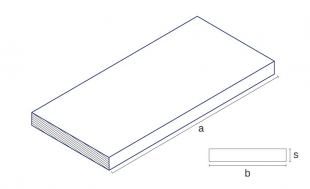

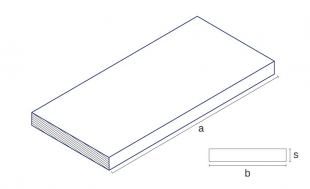

plate rolled

- Form plate rolled

- Material Bronze

- Material CW352H

- Material chemically EN 573-3 CuNi10Fe1Mn

BIKAR Metals companies

Seawater pipes

Pipes, plates and bottoms for fresh water heaters, petroleum refining plants, air-conditioning systems and apparatus engineering

Pipes, pipe linings, plates and bottoms for heat exchangers

Ccondensers as well as feedwater heaters (low pressure)

Ship hull linings

Hydraulic and pneumatic lines in mechanical engineering

Highly stressed shut-off devices subject to corrosion and wear

Line pipes for salt and other aggressive solutions

Intercoolers and oil coolers as well as honeycomb coolers in automobile and aircraft construction

Hydraulic and pneumatic lines in mechanical engineering

Feed water heaters and stirred tanks, pipes

Apparatus for food packaging, conveying and processing

| Aviation | No |

| Co (from) | 0,1 |

| Co (to) | 0,1 |

| Cu (from) | 86 |

| Cu (to) | 89,7 |

| Fe (from) | 1 |

| Fe (to) | 2 |

| Mn (from) | 0,5 |

| Mn (to) | 1 |

| Ni (from) | 9 |

| Ni (to) | 11 |

| P (from) | 0,02 |

| P (to) | 0,02 |

| Pb (from) | 0,02 |

| Pb (to) | 0,02 |

| S (from) | 0,05 |

| S (to) | 0,05 |

| Sn (from) | 0,03 |

| Sn (to) | 0,03 |

| Zn (from) | 0,5 |

| Zn (to) | 0,5 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi10Fe1Mn |

| Material no | CW352H (2.0872) |

| Coefficient of thermal expansion from 20 to 300°C | 17 K⁻¹10⁻⁶ |

| Density | 8.9 g/cm³ |

| Modulus of elasticity at 20°C | 135 GPa |

| Specific electrical conductivity at 20°C | 5 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 5 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.19 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.22 Ω*mm²/m |

| Specific heat at 20°C | 0.38 J/(kg·K) |

| Thermal conductivity at 20°C | 50.2 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 5 |

| MIG | 1 |

| TIG | 1 |

| Aviation | No |

| Co (from) | 0,1 |

| Co (to) | 0,1 |

| Cu (from) | 86 |

| Cu (to) | 89,7 |

| Fe (from) | 1 |

| Fe (to) | 2 |

| Mn (from) | 0,5 |

| Mn (to) | 1 |

| Ni (from) | 9 |

| Ni (to) | 11 |

| P (from) | 0,02 |

| P (to) | 0,02 |

| Pb (from) | 0,02 |

| Pb (to) | 0,02 |

| S (from) | 0,05 |

| S (to) | 0,05 |

| Sn (from) | 0,03 |

| Sn (to) | 0,03 |

| Zn (from) | 0,5 |

| Zn (to) | 0,5 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi10Fe1Mn |

| Material no | CW352H (2.0872) |

| Coefficient of thermal expansion from 20 to 300°C | 17 K⁻¹10⁻⁶ |

| Density | 8.9 g/cm³ |

| Modulus of elasticity at 20°C | 135 GPa |

| Specific electrical conductivity at 20°C | 5 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 5 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.19 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.22 Ω*mm²/m |

| Specific heat at 20°C | 0.38 J/(kg·K) |

| Thermal conductivity at 20°C | 50.2 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 5 |

| MIG | 1 |

| TIG | 1 |

| Aviation | No |

| Co (from) | 0,1 |

| Co (to) | 0,1 |

| Cu (from) | 86 |

| Cu (to) | 89,7 |

| Fe (from) | 1 |

| Fe (to) | 2 |

| Mn (from) | 0,5 |

| Mn (to) | 1 |

| Ni (from) | 9 |

| Ni (to) | 11 |

| P (from) | 0,02 |

| P (to) | 0,02 |

| Pb (from) | 0,02 |

| Pb (to) | 0,02 |

| S (from) | 0,05 |

| S (to) | 0,05 |

| Sn (from) | 0,03 |

| Sn (to) | 0,03 |

| Zn (from) | 0,5 |

| Zn (to) | 0,5 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi10Fe1Mn |

| Material no | CW352H (2.0872) |

| Coefficient of thermal expansion from 20 to 300°C | 17 K⁻¹10⁻⁶ |

| Density | 8.9 g/cm³ |

| Modulus of elasticity at 20°C | 135 GPa |

| Specific electrical conductivity at 20°C | 5 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 5 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.19 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.22 Ω*mm²/m |

| Specific heat at 20°C | 0.38 J/(kg·K) |

| Thermal conductivity at 20°C | 50.2 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 5 |

| MIG | 1 |

| TIG | 1 |

| Aviation | No |

| Co (from) | 0,1 |

| Co (to) | 0,1 |

| Cu (from) | 86 |

| Cu (to) | 89,7 |

| Fe (from) | 1 |

| Fe (to) | 2 |

| Mn (from) | 0,5 |

| Mn (to) | 1 |

| Ni (from) | 9 |

| Ni (to) | 11 |

| P (from) | 0,02 |

| P (to) | 0,02 |

| Pb (from) | 0,02 |

| Pb (to) | 0,02 |

| S (from) | 0,05 |

| S (to) | 0,05 |

| Sn (from) | 0,03 |

| Sn (to) | 0,03 |

| Zn (from) | 0,5 |

| Zn (to) | 0,5 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi10Fe1Mn |

| Material no | CW352H (2.0872) |

| Coefficient of thermal expansion from 20 to 300°C | 17 K⁻¹10⁻⁶ |

| Density | 8.9 g/cm³ |

| Modulus of elasticity at 20°C | 135 GPa |

| Specific electrical conductivity at 20°C | 5 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 5 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.19 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.22 Ω*mm²/m |

| Specific heat at 20°C | 0.38 J/(kg·K) |

| Thermal conductivity at 20°C | 50.2 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 5 |

| MIG | 1 |

| TIG | 1 |

| Aviation | No |

| Co (from) | 0,1 |

| Co (to) | 0,1 |

| Cu (from) | 86 |

| Cu (to) | 89,7 |

| Fe (from) | 1 |

| Fe (to) | 2 |

| Mn (from) | 0,5 |

| Mn (to) | 1 |

| Ni (from) | 9 |

| Ni (to) | 11 |

| P (from) | 0,02 |

| P (to) | 0,02 |

| Pb (from) | 0,02 |

| Pb (to) | 0,02 |

| S (from) | 0,05 |

| S (to) | 0,05 |

| Sn (from) | 0,03 |

| Sn (to) | 0,03 |

| Zn (from) | 0,5 |

| Zn (to) | 0,5 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi10Fe1Mn |

| Material no | CW352H (2.0872) |

| Coefficient of thermal expansion from 20 to 300°C | 17 K⁻¹10⁻⁶ |

| Density | 8.9 g/cm³ |

| Modulus of elasticity at 20°C | 135 GPa |

| Specific electrical conductivity at 20°C | 5 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 5 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.19 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.22 Ω*mm²/m |

| Specific heat at 20°C | 0.38 J/(kg·K) |

| Thermal conductivity at 20°C | 50.2 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 5 |

| MIG | 1 |

| TIG | 1 |

| Aviation | No |

| Co (from) | 0,1 |

| Co (to) | 0,1 |

| Cu (from) | 86 |

| Cu (to) | 89,7 |

| Fe (from) | 1 |

| Fe (to) | 2 |

| Mn (from) | 0,5 |

| Mn (to) | 1 |

| Ni (from) | 9 |

| Ni (to) | 11 |

| P (from) | 0,02 |

| P (to) | 0,02 |

| Pb (from) | 0,02 |

| Pb (to) | 0,02 |

| S (from) | 0,05 |

| S (to) | 0,05 |

| Sn (from) | 0,03 |

| Sn (to) | 0,03 |

| Zn (from) | 0,5 |

| Zn (to) | 0,5 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi10Fe1Mn |

| Material no | CW352H (2.0872) |

| Coefficient of thermal expansion from 20 to 300°C | 17 K⁻¹10⁻⁶ |

| Density | 8.9 g/cm³ |

| Modulus of elasticity at 20°C | 135 GPa |

| Specific electrical conductivity at 20°C | 5 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 5 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.19 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.22 Ω*mm²/m |

| Specific heat at 20°C | 0.38 J/(kg·K) |

| Thermal conductivity at 20°C | 50.2 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 5 |

| MIG | 1 |

| TIG | 1 |

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified