FORMODAL BM-5083

EN AW-5083

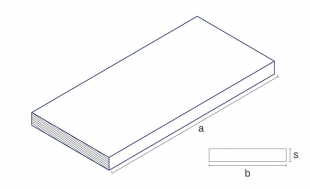

plate rolled machined surface and both sides PVC coated

- Form plate rolled machined surface and both sides PVC coated

- Material Aluminum

- Material EN AW-5083

- Material chemically EN 573-3 AlMg4,5Mn0,7

- DIN 3.3547