FORMODAL®07

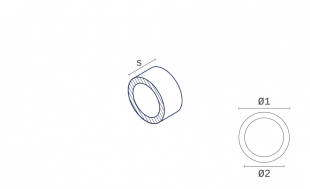

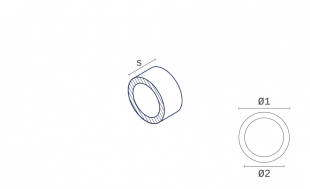

ring

- Form ring

- Material Aluminum

- Material FORMODAL®07

- Material chemically EN 573-3 Al99.5

- DIN 3.0255

| Aviation | No |

| Cu (to) | 0,05 |

| Fe (to) | 0,4 |

| Mg (to) | 0,05 |

| Mn (to) | 0,05 |

| Other | 0,03 |

| Rest | Aluminium |

| Si (to) | 0,25 |

| Ti (to) | 0,05 |

| Zn (to) | 0,07 |

| Anodise - decorative | 2 |

| Anodising - protective anodising | 1 |

| special anodising quality EQ | 1 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 2 |

| suitable according to DIN EN 602 | Yes |

| Bending | 3 |

| Deep drawing (conditional) | 4 |

| Drop forging | 1 |

| Extruding | 1 |

| Impact extrusion | 3 |

| Press | 3 |

| Upsetting (Conditional) | 3 |

| Heating time max. | 2 h |

| Heating time min. | 0.5 h |

| Annealing temperature max. | 350 °C |

| Annealing temperature min. | 320 °C |

| Cooling conditions | uncontrolled |

| dimensional stability | 1 |

| Eroding | 1 |

| soft annealed | 4 |

| Colorcode | Signal black (RAL 9004), Traffic red (RAL 3020) |

| Material chemically EN 573-3 | Al99.5 |

| DIN | 3,0255 |

| France AFNOR | A5 |

| Italy UNI | 9001/2 |

| Norway | 17.010 |

| Spain | L-3051 |

| Sweden | 144.007 |

| United Kingdom BS | 1B |

| Polishing | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C (typical) | 23.5 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C (typical) | 24.4 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C (typical) | 25.4 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from -50 to 20°C (typical) | 21.7 K⁻¹10⁻⁶ |

| Density (typical) | 2.7 g/cm³ |

| Electrical conductivity max. (typical) | 36 m/Ω*mm² |

| Electrical conductivity min. (typical) | 34 m/Ω*mm² |

| Modulus of elasticity (typical) | 69 GPa |

| Shear modulus (typical) | 25.9 GPa |

| Specific heat (typical) | 900 J/(kg·K) |

| Thermal conductivity max. (typical) | 220 W/m*K |

| Thermal conductivity min. (typical) | 210 W/m*K |

| Brazing | 1 |

| Brazing with flux | 1 |

| Friction soldering | 1 |

| Soft soldering with flux | 1 |

| Gas | 2 |

| MIG | 2 |

| Resistance spot welding | 4 |

| TIG | 2 |

| welding additives |

|

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified