AA7122

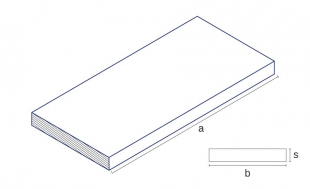

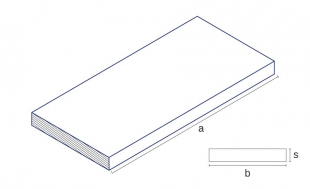

Plate - compressed

- Form Plate - compressed

- Material Aluminum

- Material AA7122

- Material chemically EN 573-3 AlZn5Mg3Cu

BIKAR Metals companies

Tool, mould and model making

Blow moulding, injection moulding, die casting and vacuum moulds

Laminating tools

Stamping technology

Die and punch holders

Mechanical engineering - constructions requiring high strength

| Aviation | No |

| Cr (from) | 0,1 |

| Cr (to) | 0,3 |

| Mg (from) | 2,6 |

| Mg (to) | 2,7 |

| Mn (to) | 0,4 |

| Si (to) | 0,5 |

| Zn (from) | 4,3 |

| Zn (to) | 5,2 |

| Anodise - decorative | 4 |

| Anodising - protective anodising | 2 |

| suitable according to DIN EN 602 | No |

| hardened | 1 |

| Material chemically EN 573-3 | AlZn5Mg3Cu |

| Polishing | 1 |

| Density | 2.76 g/cm³ |

| Aviation | No |

| Cr (from) | 0,1 |

| Cr (to) | 0,3 |

| Mg (from) | 2,6 |

| Mg (to) | 2,7 |

| Mn (to) | 0,4 |

| Si (to) | 0,5 |

| Zn (from) | 4,3 |

| Zn (to) | 5,2 |

| Anodise - decorative | 4 |

| Anodising - protective anodising | 2 |

| suitable according to DIN EN 602 | No |

| hardened | 1 |

| Material chemically EN 573-3 | AlZn5Mg3Cu |

| Polishing | 1 |

| Density | 2.76 g/cm³ |

| Aviation | No |

| Cr (from) | 0,1 |

| Cr (to) | 0,3 |

| Mg (from) | 2,6 |

| Mg (to) | 2,7 |

| Mn (to) | 0,4 |

| Si (to) | 0,5 |

| Zn (from) | 4,3 |

| Zn (to) | 5,2 |

| Anodise - decorative | 4 |

| Anodising - protective anodising | 2 |

| suitable according to DIN EN 602 | No |

| hardened | 1 |

| Material chemically EN 573-3 | AlZn5Mg3Cu |

| Polishing | 1 |

| Density | 2.76 g/cm³ |

| Aviation | No |

| Cr (from) | 0,1 |

| Cr (to) | 0,3 |

| Mg (from) | 2,6 |

| Mg (to) | 2,7 |

| Mn (to) | 0,4 |

| Si (to) | 0,5 |

| Zn (from) | 4,3 |

| Zn (to) | 5,2 |

| Anodise - decorative | 4 |

| Anodising - protective anodising | 2 |

| suitable according to DIN EN 602 | No |

| hardened | 1 |

| Material chemically EN 573-3 | AlZn5Mg3Cu |

| Polishing | 1 |

| Density | 2.76 g/cm³ |

| Aviation | No |

| Cr (from) | 0,1 |

| Cr (to) | 0,3 |

| Mg (from) | 2,6 |

| Mg (to) | 2,7 |

| Mn (to) | 0,4 |

| Si (to) | 0,5 |

| Zn (from) | 4,3 |

| Zn (to) | 5,2 |

| Anodise - decorative | 4 |

| Anodising - protective anodising | 2 |

| suitable according to DIN EN 602 | No |

| hardened | 1 |

| Material chemically EN 573-3 | AlZn5Mg3Cu |

| Polishing | 1 |

| Density | 2.76 g/cm³ |

| Aviation | No |

| Cr (from) | 0,1 |

| Cr (to) | 0,3 |

| Mg (from) | 2,6 |

| Mg (to) | 2,7 |

| Mn (to) | 0,4 |

| Si (to) | 0,5 |

| Zn (from) | 4,3 |

| Zn (to) | 5,2 |

| Anodise - decorative | 4 |

| Anodising - protective anodising | 2 |

| suitable according to DIN EN 602 | No |

| hardened | 1 |

| Material chemically EN 573-3 | AlZn5Mg3Cu |

| Polishing | 1 |

| Density | 2.76 g/cm³ |

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified