Red brass CC493K

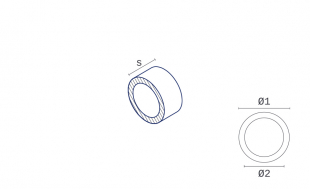

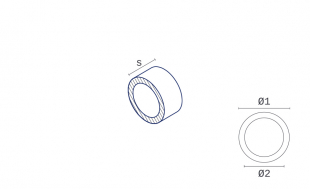

ring

- Form ring

- Material Bronze

- Material Red brass CC493K

- Material chemically EN 573-3 CuSn7ZnPb

| Aviation | No |

| Al (to) | 0,01 |

| Cu (from) | 81 |

| Cu (to) | 85 |

| Fe (to) | 0,2 |

| Ni (to) | 2 |

| P (to) | 0,1 |

| Pb (from) | 5 |

| Pb (to) | 8 |

| S (to) | 0,1 |

| Sb (to) | 0,3 |

| Si (to) | 0,01 |

| Sn (from) | 6 |

| Sn (to) | 8 |

| Zn (from) | 2 |

| Zn (to) | 5 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuSn7ZnPb |

| Material no | CC493K (2.1090.01, .03, .04) |

| Coefficient of thermal expansion from 20 to 100°C | 18 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 18.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 18.7 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 400°C | 19.1 K⁻¹10⁻⁶ |

| Density | 8.83 g/cm³ |

| Modulus of elasticity at 100°C | 94 GPa |

| Modulus of elasticity at 20°C | 101 GPa |

| Modulus of elasticity at 200°C | 88 GPa |

| Modulus of elasticity at 300°C | 85 GPa |

| Specific electrical conductivity at 20°C | 7.5 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 6.5 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.133 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.154 Ω*mm²/m |

| Specific heat at 100°C | 0.39 J/(kg·K) |

| Specific heat at 20°C | 0.38 J/(kg·K) |

| Specific heat at 200°C | 0.4 J/(kg·K) |

| Thermal conductivity at 100°C | 72 W/m*K |

| Thermal conductivity at 20°C | 64 W/m*K |

| Thermal conductivity at 200°C | 82 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 6 |

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified