UNIDAL AA7019

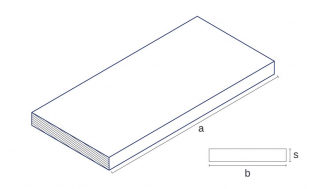

plate rolled machined surface and both sides PVC coated

- Form plate rolled machined surface and both sides PVC coated

- Material Aluminum

- Material UNIDAL AA7019

- Material chemically EN 573-3 AlZn4Mg2Mn

- DIN 3.4325