EN AW-2017A

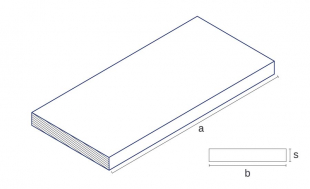

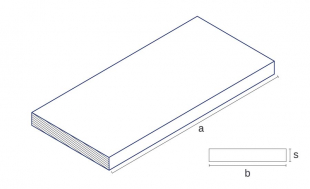

plate rolled

- Form plate rolled

- Material Aluminum

- Material EN AW-2017A

- Material chemically EN 573-3 AlCu4MgSi(A)

- DIN 3.1325

BIKAR Metals companies

Machine construction

High-strength constructions

Aerospace

Military technology

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |

| DIN (old designation) | Al Cu Mg1 |

| France AFNOR | A-U4G |

| Italy UNI | 9002/2 |

| Norway | - |

| Spain | L-3120 |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Polishing | 1 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C | 23 K⁻¹10⁻⁶ |

| Density | 2.8 g/cm³ |

| Electrical conductivity max. | 28 m/Ω*mm² |

| Electrical conductivity min. | 18 m/Ω*mm² |

| Modulus of elasticity | 72.5 GPa |

| Shear modulus | 27.2 GPa |

| Thermal conductivity max. | 200 W/m*K |

| Thermal conductivity min. | 130 W/m*K |

| Brazing | 5 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering | 5 |

| Soft soldering with flux | 5 |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 5 |

| MIG | 5 |

| Plasma | 5 |

| Resistance spot welding | 1 |

| TIG | 5 |

| Aviation | No |

| Cr (to) | 0,1 |

| Cu (from) | 3,5 |

| Cu (to) | 4,5 |

| Fe (to) | 0,7 |

| Mg (from) | 0,4 |

| Mg (to) | 1 |

| Mn (from) | 0,4 |

| Mn (to) | 1 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (from) | 0,2 |

| Si (to) | 0,8 |

| Total | 0,15 |

| Zn (to) | 0,25 |

0,25 Zr+Ti

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 3 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 4 |

| Seawater atmosphere | 4 |

| Laser cutting | 4,5 |

| Plasma cutting | 4,5 |

| Sawing | 2 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| Bending | 2 |

| Bending delivery conditions | O |

| Deep drawing (conditional) | 3 |

| Deep drawing conditions | O |

| Drop forging | 3 |

| Extruding | 4 |

| Impact extrusion | 3 |

| Impact extrusion conditions | O |

| Open die forging | 3 |

| Press | 3 |

| Press conditions | O |

| Upsetting (Conditional) | 3 |

| Upsetting conditions | O |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Annealing temperature max. | 420 °C |

| Annealing temperature min. | 380 °C |

| Cooling conditions |

Cooling conditions 30°C/h to 250°C, below 250°C in air |

| Cold ageing max. | 8 d |

| Cold ageing min. | 5 d |

| Quenching | water |

| Heating time max. | 3 h |

| Heating time min. | 2 h |

| Solution annealing max. | 505 °C |

| Solution annealing min. | 495 °C |

| cold worked | 3 |

| dimensional stability | 4 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 2 |

| soft annealed | 4 |

| Colorcode | Laubgrün (RAL 6002) |

| Material chemically EN 573-3 | AlCu4MgSi(A) |

| DIN | 3,1325 |