special brass CW713R

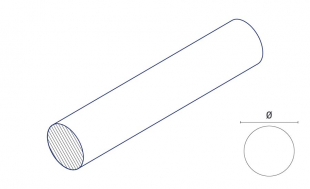

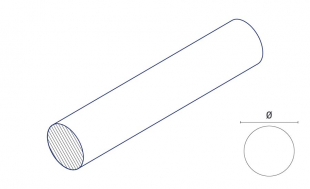

Round bar

- Form Round bar

- Material Brass

- Material special brass CW713R

- Material chemically EN 573-3 CuZn40Al2

BIKAR Metals companies

Bearing bushes and sliding elements

Construction parts for machine and vehicle construction

Valve guides, gear parts, piston rings

condenser and oil cooling tubes

various forged parts (production of tools)

Hot pressed parts of all kinds

Profiles for railing and window fittings

Bolts, rivets, pins

| Aviation | No |

| Al (from) | 1,3 |

| Al (to) | 2,3 |

| Cu (from) | 57 |

| Cu (to) | 59 |

| Fe (from) | 1 |

| Fe (to) | 1 |

| Mn (from) | 1,5 |

| Mn (to) | 3 |

| Ni (from) | 1 |

| Ni (to) | 1 |

| Other | 0,3 |

| Pb (from) | 0,2 |

| Pb (to) | 0,8 |

| Rest | Zn |

| Si (from) | 0,3 |

| Si (to) | 1,3 |

| Sn (from) | 0,4 |

| Sn (to) | 0,4 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 2 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuZn40Al2 |

| Material no | CW713R (2.0550) |

| Coefficient of thermal expansion from 20 to 100°C | 19.5 K⁻¹10⁻⁶ |

| Density | 8.12 g/cm³ |

| Modulus of elasticity at 20°C | 110 GPa |

| Specific electrical conductivity at 20°C | 8 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.125 Ω*mm²/m |

| Specific heat at 20°C | 0.377 J/(kg·K) |

| Thermal conductivity at 20°C | 63 W/m*K |

| Brazing | 5 |

| Soft soldering | 5 |

| Gas | 3 |

| MIG | 2 |

| Resistance spot welding | 2 |

| TIG | 2 |

| Aviation | No |

| Al (from) | 1,3 |

| Al (to) | 2,3 |

| Cu (from) | 57 |

| Cu (to) | 59 |

| Fe (from) | 1 |

| Fe (to) | 1 |

| Mn (from) | 1,5 |

| Mn (to) | 3 |

| Ni (from) | 1 |

| Ni (to) | 1 |

| Other | 0,3 |

| Pb (from) | 0,2 |

| Pb (to) | 0,8 |

| Rest | Zn |

| Si (from) | 0,3 |

| Si (to) | 1,3 |

| Sn (from) | 0,4 |

| Sn (to) | 0,4 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 2 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuZn40Al2 |

| Material no | CW713R (2.0550) |

| Coefficient of thermal expansion from 20 to 100°C | 19.5 K⁻¹10⁻⁶ |

| Density | 8.12 g/cm³ |

| Modulus of elasticity at 20°C | 110 GPa |

| Specific electrical conductivity at 20°C | 8 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.125 Ω*mm²/m |

| Specific heat at 20°C | 0.377 J/(kg·K) |

| Thermal conductivity at 20°C | 63 W/m*K |

| Brazing | 5 |

| Soft soldering | 5 |

| Gas | 3 |

| MIG | 2 |

| Resistance spot welding | 2 |

| TIG | 2 |

| Aviation | No |

| Al (from) | 1,3 |

| Al (to) | 2,3 |

| Cu (from) | 57 |

| Cu (to) | 59 |

| Fe (from) | 1 |

| Fe (to) | 1 |

| Mn (from) | 1,5 |

| Mn (to) | 3 |

| Ni (from) | 1 |

| Ni (to) | 1 |

| Other | 0,3 |

| Pb (from) | 0,2 |

| Pb (to) | 0,8 |

| Rest | Zn |

| Si (from) | 0,3 |

| Si (to) | 1,3 |

| Sn (from) | 0,4 |

| Sn (to) | 0,4 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 2 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuZn40Al2 |

| Material no | CW713R (2.0550) |

| Coefficient of thermal expansion from 20 to 100°C | 19.5 K⁻¹10⁻⁶ |

| Density | 8.12 g/cm³ |

| Modulus of elasticity at 20°C | 110 GPa |

| Specific electrical conductivity at 20°C | 8 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.125 Ω*mm²/m |

| Specific heat at 20°C | 0.377 J/(kg·K) |

| Thermal conductivity at 20°C | 63 W/m*K |

| Brazing | 5 |

| Soft soldering | 5 |

| Gas | 3 |

| MIG | 2 |

| Resistance spot welding | 2 |

| TIG | 2 |

| Aviation | No |

| Al (from) | 1,3 |

| Al (to) | 2,3 |

| Cu (from) | 57 |

| Cu (to) | 59 |

| Fe (from) | 1 |

| Fe (to) | 1 |

| Mn (from) | 1,5 |

| Mn (to) | 3 |

| Ni (from) | 1 |

| Ni (to) | 1 |

| Other | 0,3 |

| Pb (from) | 0,2 |

| Pb (to) | 0,8 |

| Rest | Zn |

| Si (from) | 0,3 |

| Si (to) | 1,3 |

| Sn (from) | 0,4 |

| Sn (to) | 0,4 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 2 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuZn40Al2 |

| Material no | CW713R (2.0550) |

| Coefficient of thermal expansion from 20 to 100°C | 19.5 K⁻¹10⁻⁶ |

| Density | 8.12 g/cm³ |

| Modulus of elasticity at 20°C | 110 GPa |

| Specific electrical conductivity at 20°C | 8 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.125 Ω*mm²/m |

| Specific heat at 20°C | 0.377 J/(kg·K) |

| Thermal conductivity at 20°C | 63 W/m*K |

| Brazing | 5 |

| Soft soldering | 5 |

| Gas | 3 |

| MIG | 2 |

| Resistance spot welding | 2 |

| TIG | 2 |

| Aviation | No |

| Al (from) | 1,3 |

| Al (to) | 2,3 |

| Cu (from) | 57 |

| Cu (to) | 59 |

| Fe (from) | 1 |

| Fe (to) | 1 |

| Mn (from) | 1,5 |

| Mn (to) | 3 |

| Ni (from) | 1 |

| Ni (to) | 1 |

| Other | 0,3 |

| Pb (from) | 0,2 |

| Pb (to) | 0,8 |

| Rest | Zn |

| Si (from) | 0,3 |

| Si (to) | 1,3 |

| Sn (from) | 0,4 |

| Sn (to) | 0,4 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 2 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuZn40Al2 |

| Material no | CW713R (2.0550) |

| Coefficient of thermal expansion from 20 to 100°C | 19.5 K⁻¹10⁻⁶ |

| Density | 8.12 g/cm³ |

| Modulus of elasticity at 20°C | 110 GPa |

| Specific electrical conductivity at 20°C | 8 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.125 Ω*mm²/m |

| Specific heat at 20°C | 0.377 J/(kg·K) |

| Thermal conductivity at 20°C | 63 W/m*K |

| Brazing | 5 |

| Soft soldering | 5 |

| Gas | 3 |

| MIG | 2 |

| Resistance spot welding | 2 |

| TIG | 2 |

| Aviation | No |

| Al (from) | 1,3 |

| Al (to) | 2,3 |

| Cu (from) | 57 |

| Cu (to) | 59 |

| Fe (from) | 1 |

| Fe (to) | 1 |

| Mn (from) | 1,5 |

| Mn (to) | 3 |

| Ni (from) | 1 |

| Ni (to) | 1 |

| Other | 0,3 |

| Pb (from) | 0,2 |

| Pb (to) | 0,8 |

| Rest | Zn |

| Si (from) | 0,3 |

| Si (to) | 1,3 |

| Sn (from) | 0,4 |

| Sn (to) | 0,4 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 2 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuZn40Al2 |

| Material no | CW713R (2.0550) |

| Coefficient of thermal expansion from 20 to 100°C | 19.5 K⁻¹10⁻⁶ |

| Density | 8.12 g/cm³ |

| Modulus of elasticity at 20°C | 110 GPa |

| Specific electrical conductivity at 20°C | 8 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.125 Ω*mm²/m |

| Specific heat at 20°C | 0.377 J/(kg·K) |

| Thermal conductivity at 20°C | 63 W/m*K |

| Brazing | 5 |

| Soft soldering | 5 |

| Gas | 3 |

| MIG | 2 |

| Resistance spot welding | 2 |

| TIG | 2 |

| Aviation | No |

| Al (from) | 1,3 |

| Al (to) | 2,3 |

| Cu (from) | 57 |

| Cu (to) | 59 |

| Fe (from) | 1 |

| Fe (to) | 1 |

| Mn (from) | 1,5 |

| Mn (to) | 3 |

| Ni (from) | 1 |

| Ni (to) | 1 |

| Other | 0,3 |

| Pb (from) | 0,2 |

| Pb (to) | 0,8 |

| Rest | Zn |

| Si (from) | 0,3 |

| Si (to) | 1,3 |

| Sn (from) | 0,4 |

| Sn (to) | 0,4 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 2 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuZn40Al2 |

| Material no | CW713R (2.0550) |

| Coefficient of thermal expansion from 20 to 100°C | 19.5 K⁻¹10⁻⁶ |

| Density | 8.12 g/cm³ |

| Modulus of elasticity at 20°C | 110 GPa |

| Specific electrical conductivity at 20°C | 8 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.125 Ω*mm²/m |

| Specific heat at 20°C | 0.377 J/(kg·K) |

| Thermal conductivity at 20°C | 63 W/m*K |

| Brazing | 5 |

| Soft soldering | 5 |

| Gas | 3 |

| MIG | 2 |

| Resistance spot welding | 2 |

| TIG | 2 |

| Aviation | No |

| Al (from) | 1,3 |

| Al (to) | 2,3 |

| Cu (from) | 57 |

| Cu (to) | 59 |

| Fe (from) | 1 |

| Fe (to) | 1 |

| Mn (from) | 1,5 |

| Mn (to) | 3 |

| Ni (from) | 1 |

| Ni (to) | 1 |

| Other | 0,3 |

| Pb (from) | 0,2 |

| Pb (to) | 0,8 |

| Rest | Zn |

| Si (from) | 0,3 |

| Si (to) | 1,3 |

| Sn (from) | 0,4 |

| Sn (to) | 0,4 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 2 |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuZn40Al2 |

| Material no | CW713R (2.0550) |

| Coefficient of thermal expansion from 20 to 100°C | 19.5 K⁻¹10⁻⁶ |

| Density | 8.12 g/cm³ |

| Modulus of elasticity at 20°C | 110 GPa |

| Specific electrical conductivity at 20°C | 8 m/Ω*mm² |

| Specific electrical resistance at 20°C | 0.125 Ω*mm²/m |

| Specific heat at 20°C | 0.377 J/(kg·K) |

| Thermal conductivity at 20°C | 63 W/m*K |

| Brazing | 5 |

| Soft soldering | 5 |

| Gas | 3 |

| MIG | 2 |

| Resistance spot welding | 2 |

| TIG | 2 |

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified