Nickel silverCW400J

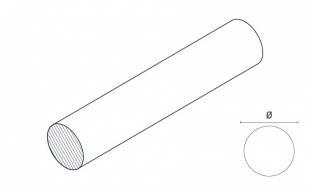

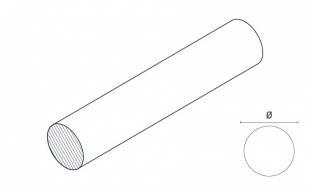

Roundbar (drawn)

- Form Roundbar (drawn)

- Material Brass

- Material Nickel silverCW400J

- Material chemically EN 573-3 CuNi7Zn39Pb3Mn2

BIKAR Metals companies

| Aviation | No |

| Cu (from) | 49 |

| Cu (to) | 49 |

| Mn (from) | 2 |

| Mn (to) | 2 |

| Ni (from) | 7 |

| Ni (to) | 7 |

| Pb (from) | 3 |

| Pb (to) | 3 |

| Rest | Zn |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi7Zn39Pb3Mn2 |

| Density | 8.44 g/cm³ |

| Modulus of elasticity at 20°C | 120 GPa |

| Thermal conductivity at 20°C | 30 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 5 |

| Resistance spot welding | 2 |

| Aviation | No |

| Cu (from) | 49 |

| Cu (to) | 49 |

| Mn (from) | 2 |

| Mn (to) | 2 |

| Ni (from) | 7 |

| Ni (to) | 7 |

| Pb (from) | 3 |

| Pb (to) | 3 |

| Rest | Zn |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi7Zn39Pb3Mn2 |

| Density | 8.44 g/cm³ |

| Modulus of elasticity at 20°C | 120 GPa |

| Thermal conductivity at 20°C | 30 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 5 |

| Resistance spot welding | 2 |

| Aviation | No |

| Cu (from) | 49 |

| Cu (to) | 49 |

| Mn (from) | 2 |

| Mn (to) | 2 |

| Ni (from) | 7 |

| Ni (to) | 7 |

| Pb (from) | 3 |

| Pb (to) | 3 |

| Rest | Zn |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi7Zn39Pb3Mn2 |

| Density | 8.44 g/cm³ |

| Modulus of elasticity at 20°C | 120 GPa |

| Thermal conductivity at 20°C | 30 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 5 |

| Resistance spot welding | 2 |

| Aviation | No |

| Cu (from) | 49 |

| Cu (to) | 49 |

| Mn (from) | 2 |

| Mn (to) | 2 |

| Ni (from) | 7 |

| Ni (to) | 7 |

| Pb (from) | 3 |

| Pb (to) | 3 |

| Rest | Zn |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi7Zn39Pb3Mn2 |

| Density | 8.44 g/cm³ |

| Modulus of elasticity at 20°C | 120 GPa |

| Thermal conductivity at 20°C | 30 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 5 |

| Resistance spot welding | 2 |

| Aviation | No |

| Cu (from) | 49 |

| Cu (to) | 49 |

| Mn (from) | 2 |

| Mn (to) | 2 |

| Ni (from) | 7 |

| Ni (to) | 7 |

| Pb (from) | 3 |

| Pb (to) | 3 |

| Rest | Zn |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi7Zn39Pb3Mn2 |

| Density | 8.44 g/cm³ |

| Modulus of elasticity at 20°C | 120 GPa |

| Thermal conductivity at 20°C | 30 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 5 |

| Resistance spot welding | 2 |

| Aviation | No |

| Cu (from) | 49 |

| Cu (to) | 49 |

| Mn (from) | 2 |

| Mn (to) | 2 |

| Ni (from) | 7 |

| Ni (to) | 7 |

| Pb (from) | 3 |

| Pb (to) | 3 |

| Rest | Zn |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi7Zn39Pb3Mn2 |

| Density | 8.44 g/cm³ |

| Modulus of elasticity at 20°C | 120 GPa |

| Thermal conductivity at 20°C | 30 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 5 |

| Resistance spot welding | 2 |

| Aviation | No |

| Cu (from) | 49 |

| Cu (to) | 49 |

| Mn (from) | 2 |

| Mn (to) | 2 |

| Ni (from) | 7 |

| Ni (to) | 7 |

| Pb (from) | 3 |

| Pb (to) | 3 |

| Rest | Zn |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi7Zn39Pb3Mn2 |

| Density | 8.44 g/cm³ |

| Modulus of elasticity at 20°C | 120 GPa |

| Thermal conductivity at 20°C | 30 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 5 |

| Resistance spot welding | 2 |

| Aviation | No |

| Cu (from) | 49 |

| Cu (to) | 49 |

| Mn (from) | 2 |

| Mn (to) | 2 |

| Ni (from) | 7 |

| Ni (to) | 7 |

| Pb (from) | 3 |

| Pb (to) | 3 |

| Rest | Zn |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi7Zn39Pb3Mn2 |

| Density | 8.44 g/cm³ |

| Modulus of elasticity at 20°C | 120 GPa |

| Thermal conductivity at 20°C | 30 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 5 |

| Resistance spot welding | 2 |

| Aviation | No |

| Cu (from) | 49 |

| Cu (to) | 49 |

| Mn (from) | 2 |

| Mn (to) | 2 |

| Ni (from) | 7 |

| Ni (to) | 7 |

| Pb (from) | 3 |

| Pb (to) | 3 |

| Rest | Zn |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | CuNi7Zn39Pb3Mn2 |

| Density | 8.44 g/cm³ |

| Modulus of elasticity at 20°C | 120 GPa |

| Thermal conductivity at 20°C | 30 W/m*K |

| Brazing | 3 |

| Soft soldering | 2 |

| Gas | 5 |

| Resistance spot welding | 2 |

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified