CW008A

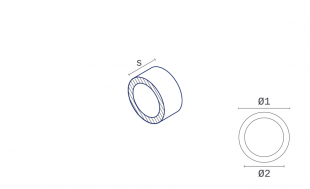

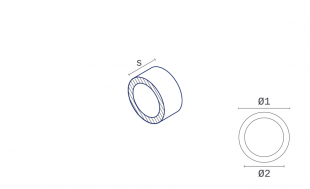

ring

- Form ring

- Material Copper

- Material CW008A

- Material chemically EN 573-3 Cu-OF

BIKAR Metals companies

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

| Aviation | No |

| Bi (to) | 0,0005 |

| O (to) | 0,001 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-OF |

| Material no | 2,004 |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 2 |

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified