CW024A

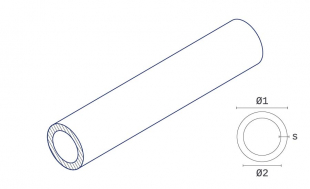

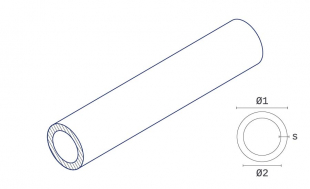

tube - round as bar drawn

- Form tube - round as bar drawn

- Material Copper

- Material CW024A

- Material chemically EN 573-3 Cu-DHP

BIKAR Metals companies

Pipes for technical and medical gases

Condensers and heat exchangers

Finned tubes for engine radiators

Refrigeration and air-conditioning systems

Pipes and apparatus parts for the food,

Beverage and paper industries

Chemical industry

Tubes for all non-corrosive liquids

External or internal cladding

Sealing in the building industry

Electrical and electromagnetic shielding

Anodes for electroplating and galvanoplastics

Pressure vessels

Storage tanks and cylinders

Pressure rollers

Clad sheets

| Aviation | No |

| P (from) | 0,015 |

| P (to) | 0,04 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-DHP |

| Material no | CW024A (former: 2.0090) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Modulus of elasticity at 100°C | 128 GPa |

| Modulus of elasticity at 20°C | 132 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 118 GPa |

| Specific electrical conductivity at 100°C | 37 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 30 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.027 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.022 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.033 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 318 W/m*K |

| Thermal conductivity at 20°C | 305 W/m*K |

| Thermal conductivity at 200°C | 334 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 1 |

| MIG | 1 |

| Resistance spot welding | 3 |

| TIG | 1 |

| Aviation | No |

| P (from) | 0,015 |

| P (to) | 0,04 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-DHP |

| Material no | CW024A (former: 2.0090) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Modulus of elasticity at 100°C | 128 GPa |

| Modulus of elasticity at 20°C | 132 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 118 GPa |

| Specific electrical conductivity at 100°C | 37 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 30 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.027 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.022 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.033 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 318 W/m*K |

| Thermal conductivity at 20°C | 305 W/m*K |

| Thermal conductivity at 200°C | 334 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 1 |

| MIG | 1 |

| Resistance spot welding | 3 |

| TIG | 1 |

| Aviation | No |

| P (from) | 0,015 |

| P (to) | 0,04 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-DHP |

| Material no | CW024A (former: 2.0090) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Modulus of elasticity at 100°C | 128 GPa |

| Modulus of elasticity at 20°C | 132 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 118 GPa |

| Specific electrical conductivity at 100°C | 37 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 30 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.027 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.022 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.033 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 318 W/m*K |

| Thermal conductivity at 20°C | 305 W/m*K |

| Thermal conductivity at 200°C | 334 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 1 |

| MIG | 1 |

| Resistance spot welding | 3 |

| TIG | 1 |

| Aviation | No |

| P (from) | 0,015 |

| P (to) | 0,04 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-DHP |

| Material no | CW024A (former: 2.0090) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Modulus of elasticity at 100°C | 128 GPa |

| Modulus of elasticity at 20°C | 132 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 118 GPa |

| Specific electrical conductivity at 100°C | 37 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 30 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.027 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.022 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.033 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 318 W/m*K |

| Thermal conductivity at 20°C | 305 W/m*K |

| Thermal conductivity at 200°C | 334 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 1 |

| MIG | 1 |

| Resistance spot welding | 3 |

| TIG | 1 |

| Aviation | No |

| P (from) | 0,015 |

| P (to) | 0,04 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-DHP |

| Material no | CW024A (former: 2.0090) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Modulus of elasticity at 100°C | 128 GPa |

| Modulus of elasticity at 20°C | 132 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 118 GPa |

| Specific electrical conductivity at 100°C | 37 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 30 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.027 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.022 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.033 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 318 W/m*K |

| Thermal conductivity at 20°C | 305 W/m*K |

| Thermal conductivity at 200°C | 334 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 1 |

| MIG | 1 |

| Resistance spot welding | 3 |

| TIG | 1 |

| Aviation | No |

| P (from) | 0,015 |

| P (to) | 0,04 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-DHP |

| Material no | CW024A (former: 2.0090) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Modulus of elasticity at 100°C | 128 GPa |

| Modulus of elasticity at 20°C | 132 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 118 GPa |

| Specific electrical conductivity at 100°C | 37 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 30 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.027 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.022 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.033 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 318 W/m*K |

| Thermal conductivity at 20°C | 305 W/m*K |

| Thermal conductivity at 200°C | 334 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 1 |

| MIG | 1 |

| Resistance spot welding | 3 |

| TIG | 1 |

| Aviation | No |

| P (from) | 0,015 |

| P (to) | 0,04 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-DHP |

| Material no | CW024A (former: 2.0090) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.94 g/cm³ |

| Modulus of elasticity at 100°C | 128 GPa |

| Modulus of elasticity at 20°C | 132 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 118 GPa |

| Specific electrical conductivity at 100°C | 37 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 30 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.027 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.022 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.033 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 318 W/m*K |

| Thermal conductivity at 20°C | 305 W/m*K |

| Thermal conductivity at 200°C | 334 W/m*K |

| Brazing | 1 |

| Soft soldering | 1 |

| Gas | 1 |

| MIG | 1 |

| Resistance spot welding | 3 |

| TIG | 1 |

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified