CW004A

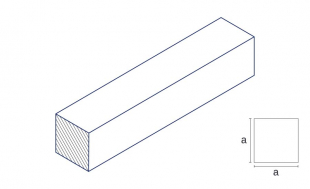

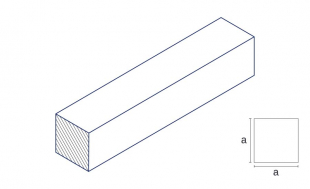

square bar

- Form square bar

- Material Copper

- Material CW004A

- Material chemically EN 573-3 Cu-ETP

BIKAR Metals companies

windings for electrical machines and apparatus

cables and wires

contact and chain wire

busbar connectors, feeder cables and switching circuits

busbars, contacts, switches

terminals, collector lamellas

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

| Aviation | No |

| Bi (from) | 0,0005 |

| Bi (to) | 0,0005 |

| Cu footnote reference | 1 |

| Other | 0,03 |

| Pb (from) | 0,005 |

| Pb (to) | 0,005 |

| Rest | Cu |

| suitable according to DIN EN 602 | No |

| Material chemically EN 573-3 | Cu-ETP |

| Material no | CW004A (former 2.0065. 2.0060) |

| Coefficient of thermal expansion from 20 to 100°C | 16.8 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C | 17.3 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C | 17.7 K⁻¹10⁻⁶ |

| Density | 8.93 g/cm³ |

| Modulus of elasticity at 100°C | 126 GPa |

| Modulus of elasticity at 20°C | 130 GPa |

| Modulus of elasticity at 200°C | 122 GPa |

| Modulus of elasticity at 300°C | 116 GPa |

| Specific electrical conductivity at 100°C | 43 m/Ω*mm² |

| Specific electrical conductivity at 20°C | 57 m/Ω*mm² |

| Specific electrical conductivity at 200°C | 33 m/Ω*mm² |

| Specific electrical conductivity at -100°C | 110 m/Ω*mm² |

| Specific electrical conductivity at -200°C | 460 m/Ω*mm² |

| Specific electrical resistance at 100°C | 0.023 Ω*mm²/m |

| Specific electrical resistance at 20°C | 0.018 Ω*mm²/m |

| Specific electrical resistance at 200°C | 0.03 Ω*mm²/m |

| Specific electrical resistance at -100°C | 0.009 Ω*mm²/m |

| Specific electrical resistance at -200°C | 0.002 Ω*mm²/m |

| Specific heat at 100°C | 0.393 J/(kg·K) |

| Specific heat at 20°C | 0.386 J/(kg·K) |

| Specific heat at 200°C | 0.403 J/(kg·K) |

| Thermal conductivity at 100°C | 385 W/m*K |

| Thermal conductivity at 20°C | 394 W/m*K |

| Thermal conductivity at 200°C | 381 W/m*K |

| Thermal conductivity at -100°C | 435 W/m*K |

| Thermal conductivity at -200°C | 574 W/m*K |

| Brazing | 2 |

| Soft soldering | 1 |

| Gas | 6 |

| MIG | 5 |

| TIG | 5 |

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified