FORMODAL® 036 high-strength

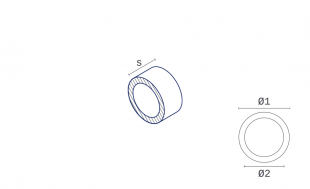

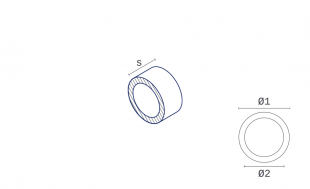

Ring - machined surface

- Form Ring - machined surface

- Material Aluminum

- Material FORMODAL® 036 high-strength

- Material chemically EN 573-3 7021

- DIN -

| Aviation | No |

| Anodise - decorative | 5 |

| Anodising - protective anodising | 2 |

| Chromating | 2 |

| Cleaning / degreasing | 2 |

| Hard anodising | 2 |

| Phosphating | 2 |

| Pickling | 2 |

| Shining | 4,5 |

| Normal atmosphere | 2 |

| Seawater atmosphere | 4 |

| Laser cutting | 3 |

| Plasma cutting | 2 |

| Sawing | 1 |

| Shear cutting | 2 |

| Waterjet cutting | 1 |

| suitable according to DIN EN 602 | No |

| dimensional stability | 1 |

| Eroding | 1 |

| Etching | 2 |

| hardened | 1 |

| Photo etching | 4 |

| Material chemically EN 573-3 | 7.021 |

| DIN | - |

| DIN (old designation) | - |

| France AFNOR | - |

| Italy UNI | - |

| Norway | - |

| Spain | - |

| Sweden | - |

| United Kingdom BS | - |

| Blasting | 1 |

| Brushing | 2 |

| Grinding | 2 |

| Galvanising | 2 |

| Nickel coating | 2 |

| Thermal spraying | 4 |

| Enamelling | 5 |

| Laminating | 2 |

| Coefficient of thermal expansion from 20 to 100°C (typical) | 23.7 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 200°C (typical) | 23.7 K⁻¹10⁻⁶ |

| Coefficient of thermal expansion from 20 to 300°C (typical) | 23.7 K⁻¹10⁻⁶ |

| Density (typical) | 2.78 g/cm³ |

| Electrical conductivity max. (typical) | 23 m/Ω*mm² |

| Electrical conductivity min. (typical) | 19 m/Ω*mm² |

| Modulus of elasticity (typical) | 72 GPa |

| Thermal conductivity min. (typical) | 150 W/m*K |

| Friction stir welding | 2 |

| Friction welding | 2 |

| Gas | 5 |

| Laser | 2 |

| MIG | 5 |

| Plasma | 2 |

| Resistance spot welding | 1 |

| TIG | 2 |

| welding additives |

|

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified