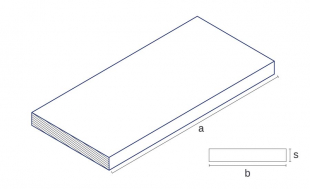

FORMODAL 030

FORMODAL® 023

cast plate machined surface and both sides PVC coated

- Form cast plate machined surface and both sides PVC coated

- Material Aluminum

- Material FORMODAL® 023

- Material chemically EN 573-3 AlMg4.5Mn0.7

- DIN 3.3547