FORMODAL®019 elox

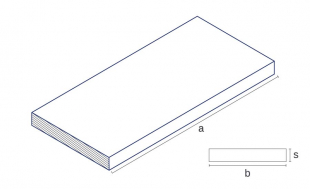

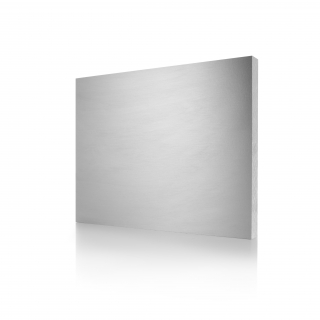

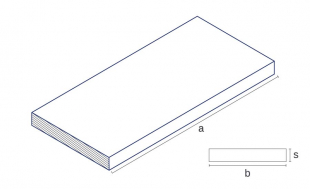

cast plate machined surface and both sides PVC coated

- Form cast plate machined surface and both sides PVC coated

- Material Aluminum

- Material FORMODAL®019 elox

- Material chemically EN 573-3 AlMg3

| Aviation | No |

| Cr (to) | 0,3 |

| Cu (to) | 0,1 |

| Fe (to) | 0,4 |

| Mg (from) | 2,6 |

| Mg (to) | 3,6 |

| Mn (to) | 0,5 |

| Other | 0,05 |

| Rest | Aluminium |

| Si (to) | 0,4 |

| Ti (to) | 0,15 |

| Total | 0,15 |

| Zn (to) | 0,2 |

| Anodise - decorative | 2 |

| Anodising - protective anodising | 1 |

| Normal atmosphere | 1 |

| Seawater atmosphere | 1 |

| suitable according to DIN EN 602 | Yes |

| Bending | 4 |

| Deep drawing (conditional) | 5 |

| Drop forging | 1 |

| Extruding | 1 |

| Impact extrusion | 4 |

| Open die forging | 1 |

| Press | 4 |

| Upsetting (Conditional) | 4 |

| Annealing temperature min. | 345 °C |

| dimensional stability | 1 |

| Eroding | 2 |

| Material chemically EN 573-3 | AlMg3 |

| France AFNOR | - |

| Italy UNI | - |

| Norway | - |

| Spain | - |

| Sweden | - |

| United Kingdom BS | - |

| Polishing | 2 |

| Painting / Coating | 3 |

| Coefficient of thermal expansion from 20 to 100°C (typical) | 23.9 K⁻¹10⁻⁶ |

| Density (typical) | 2.67 g/cm³ |

| Electrical conductivity max. (typical) | 23 m/Ω*mm² |

| Electrical conductivity min. (typical) | 20 m/Ω*mm² |

| Modulus of elasticity (typical) | 70 GPa |

| Specific heat (typical) | 900 J/(kg·K) |

| Thermal conductivity max. (typical) | 160 W/m*K |

| Thermal conductivity min. (typical) | 130 W/m*K |

| Brazing | 4 |

| Brazing with flux | 5 |

| Friction soldering | 3 |

| Soft soldering with flux | 5 |

| Gas | 2 |

| MIG | 1 |

| Resistance spot welding | 3 |

| TIG | 1 |

| welding additives |

|

1 very good

2 good

3 moderate

4 poor

5 unsuited

0 Not specified